Be prepared for all track challenges

Ensure long-term rail safety with continuous rail testing and our ultrasonic rail testing solution. Identify hidden defects before they cause failures, reduce maintenance costs and extend track life.

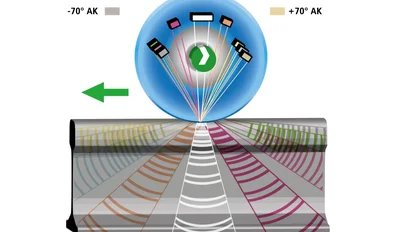

With the SoniQ Rail Explorer – a joint development of Vossloh and the Fraunhofer IKTS – you will discover the future of mobile ultrasonic inspection. Our smart solution ensures precise defect detection, keeping tracks safe and reliable. With advanced technology and data-driven insights, rail maintenance becomes even more time and cost efficient. See now how you can keep your rail tracks monitored and maintained.

Is the SoniQ Rail Explorer right for your track maintenance needs? Choose between purchasing your own SoniQ Rail Explorer including training and software or having your rails inspected as a service. We’ll be happy to advise you. Let’s talk!

.jpg?format=webp&quality=85&crop=956.4,956,x372.1,y229.9&width=60)